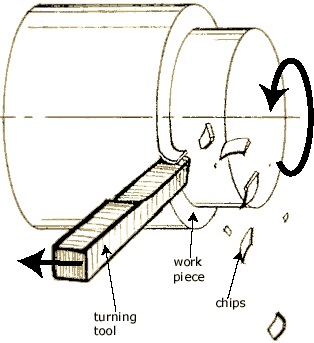

PRINCIPLE OF TURNING OPERATION

-

Turning operation is a form of machining operation where the material is removed by the process which includes the rotational parts by cutting away the unwanted material.

-

The cutting tool remains constant while the workpiece is in rotational motion.

WHAT IS METAL CUTTING?

Metal cutting is an operation that involves the removal of unwanted or extra metal layers to achieve the desired shape and size.

In this operation force is applied, pressure is exerted on the workpiece, and metal gets compressed near the tip of the tool.

DEFINE CUTTING SPEED, FEED, AND DEPTH OF CUT REGARDING LATHE OPERATIONS?

Cutting Speed

It is the speed at which the workpiece moves with respect to the cutting tool.

Cutting Speed = (π x D x N) / 60 x 1000 mm/min

D = diameter of the workpiece (mm)

N = rpm of the workpiece

Feed

Feed rate is the distance between the cutting tool travels during one revolution of the workpiece.

Depth of Cut

The distance that tool moves into the workpiece is called depth of cut.

Depth of Cut = (D – d)/2 mm

D = outer diameter

d = inner diameter

What is the tool signature and briefly explain it?

It is a numerical code that explains the key angles of a given cutting tool. It’s the standardized abbreviated system used to specify tool angles and it’s also known as tool nomenclature.

What is the chip reduction coefficient?

It’s the ratio of chip thickness to that of uncut chip thickness.

What is the difference between Single point and multipoint cutting tools?

1 Single point cutting tool has only one main cutting edge whereas a multipoint cutting tool has more than one cutting edge in the cutter body.

2 Design and manufacturing of Single point is easier comparative to multipoint cutting tools

3 Depth of cut and feed rate is usually low in case of single point cutting tool whereas in multipoint cutting tool these two factors are high.

4 Here material removal rate is lower than that of the Multipoint cutting tool

5 Shaping tools, planning tool, slotting tool are some examples of single-point cutting tools whereas Milling cutter, broach, grinding wheel are examples of multi-point cutting tools.

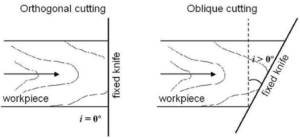

What are orthogonal and oblique cutting?

Orthogonal Cutting Tool

The cutting edge of the tool is perpendicular to that of cutting velocity factor. The Orthogonal Cutting tool is perfectly sharp and only the cutting edge is in action.

Oblique Cutting Tool

The cutting edge of the tool is inclined at an angle to that of the cutting velocity factor. Oblique Cutting tool is not very perfectly sharp and more than one cutting edge is involved in action.