WELDABILITY

OF Al AND IT’S ALLOYS

Aim

To investigate the weldability of Aluminum and its

Alloys.

Objectives

1 To know the weldability of Aluminum

2 To know the weldability of Some of

the Alloys of Aluminum

Abstract

A material’s weldability, also known as joinability,

relates to its ability to be welded. Welding may be done on a variety of metals

and thermoplastics, but some are easier to work with than others. The

weldability of a material is used to determine the welding procedure and to

compare the quality of the finished weld to that of other materials. Specific commercial alloys are

designated by a four-digit designation based on international requirements for

wrought alloys or the ISO alpha-numeric system. Non-heat-treatable alloys and

heat-treatable alloys can be further classed based on how the alloying elements

develop mechanical properties.

Keywords – Aluminum alloys, aluminum oxide, shielding gases,

anodizing, aluminum welding process selection.

Introduction

Due

to favorable qualities like as light weight, ease of machining, and corrosion

resistance, aluminum and its alloys have become more important in structural

engineering. This article discusses the surface-related issues that aluminium

welding faces, notably weld process and joint restrictions. The methodological

approach consists of a thorough assessment of published literature and results

based on eight industrial aluminium welding procedures and six joint types. It

is demonstrated that issues such as heat input control, hot cracking, porosity,

and weldable thickness vary depending on the technique utilized, and that there

is no one-size-fits-all weld process for all aluminium alloys and thicknesses.

A table is provided to aid in the selection of the best process for a certain

application. This study demonstrates the importance of understanding weld constraints

when choosing appropriate welding procedures.

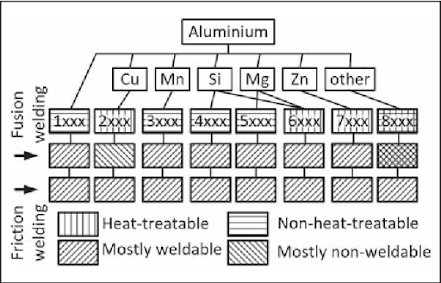

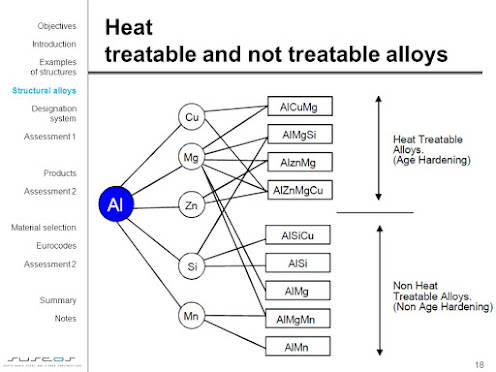

Material Type

Because

pure aluminum is rather soft, alloying elements are added in small amounts to

give a variety of mechanical qualities. Specific commercial alloys are

designated by a four-digit designation based on international requirements for

wrought alloys or the ISO alpha-numeric system. Non-heat-treatable alloys and

heat-treatable alloys can be further classed based on how the alloying elements

develop mechanical properties.

Process factors

While

weldability can be defined broadly for a variety of materials, some welding

methods are better suited to particular materials than others. The quality of a

weld can vary substantially even within a single operation, depending on

variables such as electrode material, shielding gases, welding speed, and

cooling rate.

Non-heat-treatable alloys

Work

hardening and solid solution hardening of alloy elements such as magnesium and

manganese determine material strength; alloying elements are mostly found in

the 1xxx, 3xxx, and 5xxx series of alloys. These alloys may lose their work

hardening properties when welded, resulting in softening of the HAZ next to the

weld.

Heat-treatable alloys

The hardness

and strength of a material are determined by its alloy composition and heat

treatment (solution heat treatment and quenching followed by either natural or artificial

ageing produces a fine dispersion of the alloying constituents). The 2xxx,

6xxx, and 7xxx series specify the main alloying components. The hardening

components in the HAZ are redistributed during fusion welding, reducing

material strength locally.

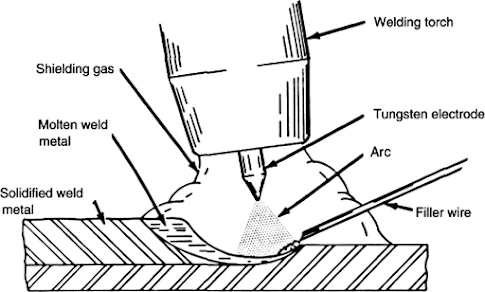

Processes

TIG, MIG,

and oxyfuel procedures can be used to fusion weld most wrought grades in the

1xxx, 3xxx, 5xxx, 6xxx, and medium strength 7xxx (e.g. 7020) series.

Weldability is particularly good in the 5xxx family alloys. Because of the risk

of liquation and solidification cracking, high strength alloys (e.g. 7010 and

7050) and most of the 2xxx series are not suggested for fusion welding.

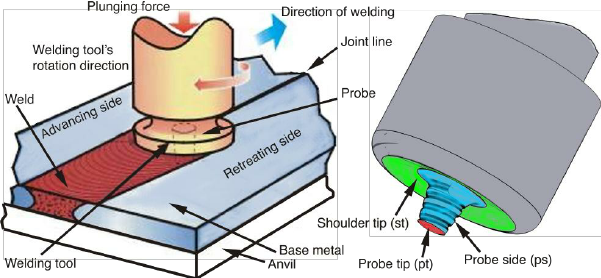

Friction Stir Welding is a process that works well with

aluminum alloys. It can produce sound welds in a wide range of alloys,

including heat treatable metals that are prone to hot cracking during fusion

welding.

Friction Stir Welding of Aluminum

Aluminum Arc Welding

Filler Alloys

The composition of the filler metal is governed by:

1: The parent metal’s weldability

2: The weld metal’s minimal mechanical characteristics

3: Resilience to corrosion

4: Criteria for anodic coating

Non-heat-treatable alloys are frequently filled with

nominally corresponding filler metals. Non-matching fillers are used to prevent

solidification cracking in alloy-lean materials and heat-treatable alloys.

For TIG and MIG welding, BS EN 1011 Pt 4:2000 specifies the

filler metal composition for the various weldable alloys; recommended filler

metal compositions for the more widely used metals are given in the Table.

References

1 https://en.wikipedia.org/wiki/Weldability#Aluminium

3 https://en.wikipedia.org/wiki/Weldability#Aluminium

4https://www.tandfonline.com/doi/abs/10.1080/09507110109549361?journalCode=twld20

7https://link.springer.com/article/10.1007/s13632-020-00675-w