Introduction

3D printing, also known as “Additive Manufacturing,” is a technique for converting digital designs into actual products by layering them together. On this technology, 4D printing is built. With one major exception: it makes use of unique materials and complex patterns that are “programmed” to cause your 3D print to alter shape. In essence, 4D printing is a refinement of 3D printing in which specific materials are used to make items that change shape after they are printed. Water, heat, wind, and other types of energy could all act as a catalyst.

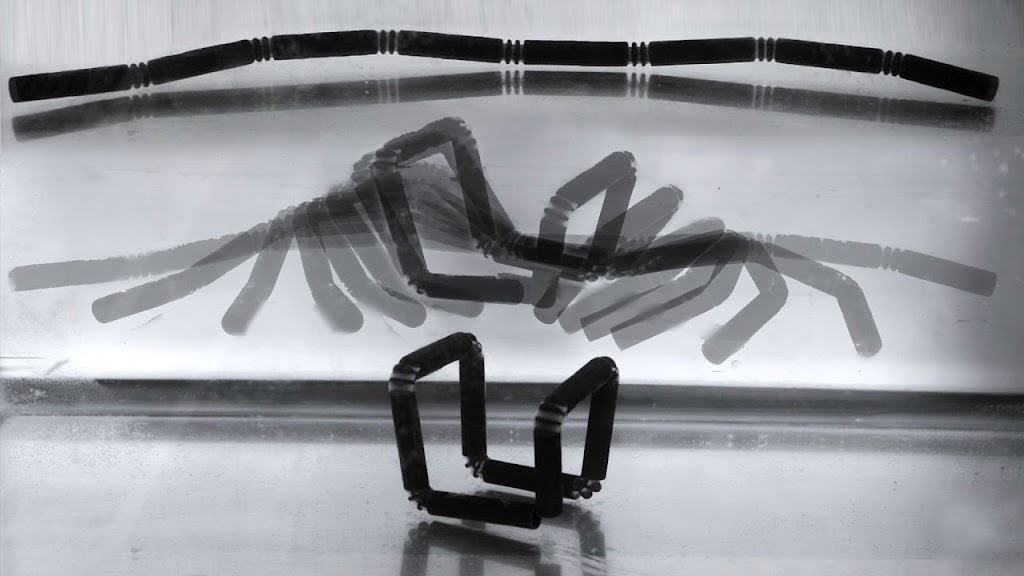

3D printed things with 4D printing have the potential to change shape over time. The phrase “4D printing” refers to the addition of a fourth dimension to the printing process: time. 3D printing processes are combined with high-level material science, engineering, and software in this new technology. 4D printing relies on materials that have been precisely developed to react to a specific stimuli, therefore materials are vital. Temperature fluctuations, light, water, magnetic fields, as well as chemical and other environmental elements, are all common triggers that can cause created things to morph. 4D printed items may fold or unfold themselves in specified shapes when prompted by an external source, opening the door to a variety of intriguing applications that we’ll look at below.

Materials Used in 4D Printing

Hydrogels

The hydrophilic networks of polymers are hydrophilic, with substantial quantities of water retainable. Hydrogels can be programmed to alter shape in response to temperature changes and used in UV-curable 3D printing processes. Hydrogels are biocompatible and thus well-suited to medical applications due to their primarily water composition. Soft robotics and flexible electronics are two examples of applications where hydrogels can be used. When exposed to temperature fluctuations, the hydrogel substance alters its form. This development could enable new applications in soft robotics such as flexible sensors and actuators, as well as further development of biomedical applications.

Shape-memory polymers

Shape-memory polymers (SMPs) are polymer-smart materials which, when exposed to an external stimuli, can shift from a fixed temporary shape to their original form. SMPs have found several uses in aerospace, soft robots, biomedicals and other areas, due to their active action capacity (the ability to move and regulate mechanisms or systems).

Shape-memory alloys

Shape-memory alloys (SMAs) are intelligent metal materials that retain a “memory” of their originally design similar to SMPs and, following deformation, can return to that original shape under stimuli. SMAs can find applications in a wide range of fields, including aerospace, civil engineering and biomedical equipment.

Ceramics

Last year, a research team from the City University of Hong Kong demonstrated a novel ceramic ink, which combines polymers and ceramic nanoparticles.

The 3D-printed ceramic precursors printed with this ink are soft and can be stretched three times beyond their initial length. Some of the promising applications of this material include electronic devices as well as applications within the aerospace industry.

However, this methodology may take 3-5 working days to course of your payouts. All regulated casinos are user-friendly, reflecting the correct investment behind the sight design and its operations. However, you need to} avoid casinos with broken hyperlinks which are complicated to navigate via. While giving BetOnline the benefit of|the good factor about|the benefit of} the doubt for its not-so-ideal beginning, we 카지노 사이트 will to} safely say BetOnline has addressed all the problems its clients faced up to now.